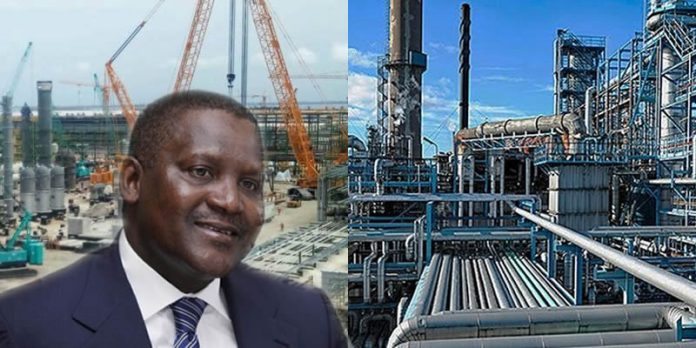

The 650,000 barrels per day Dangote Refinery, which will start operating on Monday (today), has been built to handle crude oil grades from the three continents of Africa, Asia, and America. Additionally, it was learned that the oil processing plant will supply Nigeria with an excess of nearly 38 million liters of gasoline, diesel, kerosene, and aviation fuel per day, fully satisfying the nation’s need for fuel.

The Dangote Refinery could enable the creation of 26,716 filling stations, generate 100,000 direct and indirect employment, and provide a $21 billion market for Nigerian crude oil yearly, according to data in a document that was received from the firm on Sunday.

The Dangote Refinery, established by Africa’s richest man, Aliko Dangote, is scheduled to be inaugurated on May 22. A presidential aide, Bashir Ahmad, had tweeted that the inauguration would be done by the President, Major General Muhammadu Buhari (retd.).

“Efforts by the Federal Government to make Nigeria self-sufficient in local refining of crude oil to save the scarce foreign exchange used in the importation of petroleum products have received a boost as the 650,000 barrels per day Dangote Refinery, the world’s largest single-train refinery, is set for inauguration on May 22nd, 2023, by President Muhammadu Buhari,” Ahmad announced.

The Dangote Petroleum Refinery and Petrochemical Project, a subsidiary of Dangote Industries Limited, is a 650,000 barrels per day crude oil refinery, located in Dangote Industries Free Zone, Ibeju-Lekki, Lagos, Nigeria.

The Dangote Petroleum Refinery is an industrial plant that transforms crude oil into various usable petroleum products such as diesel, gasoline, jet fuel and kerosene. Dangote Petroleum Refinery with a capacity to refine 650,000 barrels of crude oil per day covers an area of approximately 2,635 hectares in the Lekki Free Trade Zone in Lagos.

The refinery will produce Euro-V quality gasoline and diesel, as well as jet fuel and polypropylene. The firm stated that the facility was “designed to process a large variety of crudes including many of the African crudes, some of the Middle Eastern crudes and the US (United States) Light Tight Oil.”

On the target market and petroleum sufficiency, it stated that the refinery could meet 100 per cent of the Nigerian requirement of all liquid products, including gasoline (petrol), diesel, kerosene and aviation jet, and would also have a surplus of each of these products for export.

“The refinery is designed to use the latest technology to comply with stringent guidelines and regulations to protect the local environment, and at the same time produce the latest environmentally friendly petroleum products for worldwide markets,” the document from the firm stated.

On fuel requirements in Nigeria and supply from the refinery, the document showed that the facility would produce a daily surplus of 38 million litres of petrol, kerosene, aviation fuel and diesel.

It stated that the refinery would produce a surplus of about 20 million litres of petrol daily, a surplus of one million litres of kerosene daily, a surplus of one million litres of JetA1 daily, and a surplus of 16 million litres of diesel daily. For product evaluation, the refinery’s dispatch facilities by road (tanker) for the product (gasoline, diesel, kerosene/jet fuel, propane and slurry) is up to 80 per cent of the total production and up to 75 per cent through marine facilities.

It has a year-round operation for road loading operation, with a total of 177 tank farms with a capacity of 4.74 billion litres, and a total tanker loading of 2,900. “This number is based on a tanker capacity of 33 KL,” the firm stated. It explained that the Dangote Refinery project was particularly complex, featuring engineering, procurement, construction, pre-commissioning, and related storage facilities, all located in the Dangote Industries Free Zone Area of Ibeju-Lekki, Lagos.

“Dangote is one of the few companies in the world executing a petroleum refinery and a petrochemical complex directly as an Engineering, Procurement, and Construction contractor. Globally, apart from three companies, no individual owner has done the complete EPC contract for a petroleum refinery,” it stated.

The document further pointed out that the total number of temporary housing in the premises was for 33,000 people. The refinery has its own dedicated steam and power generation system with adequate standby units for reliable/uninterrupted utility supply to operating plants. The power plant has a capacity of 435MW.

For the roll-on/roll-off quay, the document stated that Dangote Industries had developed a port and constructed quays with a load-bearing capacity of 25 tonnes/sq-meter to bring Over Dimensional Cargoes close to the site directly to handle liquid cargoes.

It stated that the jetty was situated at a distance of 12.3km from the refinery thereby effectively reducing the travel time, adding that there were over 1,029 trucks to improve the capacity of the local logistics.

On employment generation, the firm stated that the facility had a capacity of generating over 100,000 indirect employment at retail outlets, 26,716 filling stations and 129 depots in Nigeria, ease of availability of products by helping to open up service stations, and 16,000 trucks for transport that would create additional jobs.

It stated that over 30,000 were currently working at the petroleum refinery project site, through various contractors.

“When operational, the petroleum refinery is going to generate over 100,000 direct and indirect jobs for Nigerian youths,” the firm stated.

Buttressing on other forms of investments in the facility, the document stated that 70 per cent of the site was swamp and the land had to be reclaimed. It stated that 65 million cubic metres of sand filling, costing approximately 300m euro, was invested to elevate the height of the plant by 1.5 metres, and to insure against any potential impact of the increase in mean sea level due to global warming.

For civil construction, it stated that “we bought over 1,209 pieces of equipment to enhance the local capacity for site works since even Julius Berger, Dantata & Sawoe, Hi-Tech, etc, are unable to handle some portions of our construction requirement.

“In mechanical construction, we bought 332 cranes to build up equipment installation capacity since the current capacity in Nigeria is extremely poor.”